The dispersion machine adopts stepless speed control: electromagnetic speed control, frequency control (such as for water-based paint) and explosion-proof frequency control (such as for oil-based paint) and other forms. The stepless speed regulation function can fully meet the different process requirements in each process, and different speed can be selected according to different process stages. The powder does not add additives, and the material with high requirements for the integrity of the crystal package is not suitable.

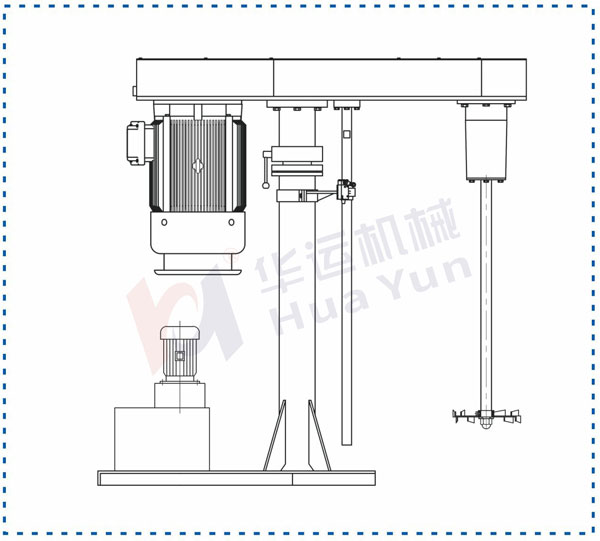

The dispersion plate of the dispersing machine is in a laminar flow state, and the slurry layers with different flow rates are diffused with each other to play a dispersing role. The high speed dispersing machine has many functions such as hydraulic lifting, 360 degree rotation, stepless speed regulation and so on. It can be configured with 2-4 containers at the same time, the hydraulic lifting stroke is 1000mm, and the 360-degree rotation function can better meet the multi-purpose of one machine, and can be changed from one cylinder to another cylinder in a very short time. The dispersion machine greatly improves the work efficiency and reduces the labor intensity.

The dispersing machine forms a turbulent zone at the edge of the dispersing disc 2.5-5mm, and the slurry and particles are subjected to strong shear and impact.

The dispersing machine mainly pulverizes, disperses, emulsifies and mixes liquid raw materials with different viscosity slurry. Through the new efficient mixing equipment with high speed and high speed running of the upper and lower serrated parts of the dispersing plate, the material is subjected to high speed and strong shear, impact, crushing and dispersing to achieve the function of rapid mixing, dissolution, dispersion and refinement. Feed area, while axial suction from the working chamber.

a. The strong centrifugal force throws the material radially into the narrow and precise gap between stator and rotor. At the same time, the material is initially dispersed by the combined force of centrifugal extrusion, liquid layer friction and hydraulic impact.

b. The high-speed rotating rotor of the dispersion machine produces a linear speed of at least 15m/s, and the material is fully dispersed and broken under the action of strong hydraulic shear, liquid layer friction, tearing collision, etc., and is shot through the stator groove at high speed.

c. The material of the dispersing machine is continuously emitted from the radial high-speed, changing the flow direction under the resistance of the material itself and the container wall, and at the same time, under the action of the upper and lower axial suction generated in the rotor area, the upper and lower two strong turbulent flows are formed. The material goes through several cycles and finally completes the dispersion process.

H |

F |

L |

105- |

4 |

|||||

Company code |

Disperse machine |

Product class |

Product Model |

Drive power |

Model |

Capacity (L) |

Motor (Kw) |

Rotate speed(rpm) |

Diameter (mm) |

lift distance (mm) |

Hydraulic motor (Kw) |

Length (mm) |

Width (mm) |

Height (mm) |

Weight(Kg) |

|||||||||||

HFL-4 |

≤200 |

4 |

0-1450 |

200 |

850 |

0.75 |

1360 |

420 |

1530 |

600 |

|||||||||||

HFL-7.5 |

≤400 |

7.5 |

0-1450 |

230 |

850 |

1.1 |

1490 |

460 |

1640 |

800 |

|||||||||||

HFL-11 |

≤500 |

11 |

0-1450 |

250 |

1000 |

1.1 |

1670 |

500 |

1820 |

1000 |

|||||||||||

HFL-15 |

≤700 |

15 |

0-1450 |

280 |

1000 |

1.1 |

1670 |

500 |

1820 |

1100 |

|||||||||||

HFL-18.5 |

≤800 |

18.5 |

0-1450 |

300 |

1200 |

2.2 |

1890 |

640 |

2000 |

1300 |

|||||||||||

HFL-22 |

≤1000 |

22 |

0-1450 |

350 |

1200 |

2.2 |

1890 |

640 |

2000 |

1400 |

|||||||||||

HFL-30 |

≤1500 |

30 |

0-1450 |

400 |

1200 |

2.2 |

2020 |

700 |

2180 |

1500 |

|||||||||||

HFL-37 |

≤2000 |

37 |

0-1450 |

400 |

1200 |

2.2 |

2020 |

700 |

2180 |

1600 |

|||||||||||

HFL-45 |

≤2500 |

45 |

0-1450 |

450 |

1500 |

2.2 |

2200 |

750 |

2350 |

1900 |

|||||||||||

HFL-55 |

≤3000 |

55 |

0-1450 |

500 |

1500 |

2.2 |

2440 |

780 |

2350 |

2100 |

|||||||||||

HFL-75 |

≤4000 |

75 |

0-960 |

550 |

1800 |

3 |

2580 |

800 |

2850 |

2300 |

|||||||||||

HFL-90 |

≤6000 |

90 |

0-960 |

600 |

1800 |

3 |

2700 |

820 |

3100 |

2600 |

|||||||||||

HFL-110 |

≤8000 |

110 |

0-960 |

700 |

2200 |

3 |

2880 |

850 |

3350 |

3100 |

E-mail:huayuncompany@126.com

Factory address:No.25, Jinhai Road, Shuangfeng

Economic& Development district,Hefei, Anhui,CN

Marketing&Sales office:Floor 13th , Meidi

Yangguang mansion,Jinzhai road, Hefei City.

Copyright 2018 Hefei Huayun Machinery

Manufacturing Co., Ltd

*Part of the webpage materials and related resources on this site are from the Internet.

If there is any infringement, please inform us immediately and we will delete it within 24 hours*